The Group's products and business mainly comprises production and sales of yarns, garment fabrics and apparel, of which the yarn segment has accounted for over 75%. For the yarn segment, products are mainly produced through physical spinning process, and eco-friendly raw materials are using as much as possible to meet the requirements from customers. Besides, the spinning production process does not involve the use of chemicals, colorants and waste water discharge from printing or start dyeing, thereby with less impact on the environment; for the garment fabrics and apparel segment, we have also formulated comprehensive sustainability goals and plans to reduce its environmental impact.

STRATEGIES AND

OBJECTIVES

STRATEGIES AND

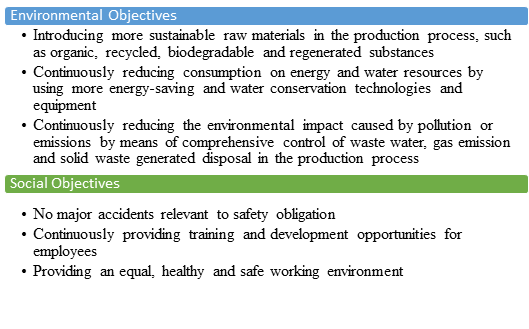

OBJECTIVESSustainability is the core of Texhong International Group’s development strategy.We integrate the concept of sustainability into all situations such as procurement, transportation, production and sales, to become a sustainable textile manufacturer through the practice of 3R principles:Reduce, Reuse and Recycle.

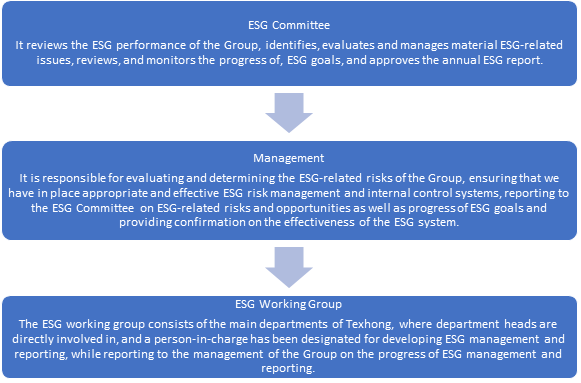

In order to establish a top-down ESG improvement mechanism with long-term effects so as to promote the sustainability of Texhong International Group, we has explicitly specified the requirements on our directors in terms of ensuring ESG compliance, improving the quality of ESG reporting and optimizing ESG work in their performance appraisals. Compliance of ESG indicators will be regarded as an adjustment factor for the determination of the year-end bonus of the directors. We have also established relevant punishment mechanisms and set up levels of punishment according to the severity of negative ESG incidents, if any.

In order to promote environmental sustainability, the Group actively cooperates with suppliers and brands to jointly reduce the environmental impact of operating activities.

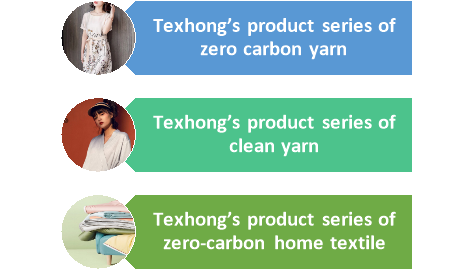

The Group actively sources natural, recycled, biodegradable and sustainable materials when continuously improving its production process.In addition, we have in-depth cooperation with famous fibre suppliers to realise the production of low-carbon yarns by using materials such as zero-carbon TENCEL Lyocell and MODAL products .A professional production line for zero-carbon or low-carbon products is planned to be built soon.Meanwhile, we have participated in environmental protection projects such as Clean-by-design, Climate Roadmap and Real Good of the brands.In particular, Clean-by-design has initiated by the Natural Resources Defense Council(NRDC), aims at eventually achieving revolutionary changes in the global supply chain by assessing and implementing economically viable solutions at the factory level to save energy and water and to reduce pollution.

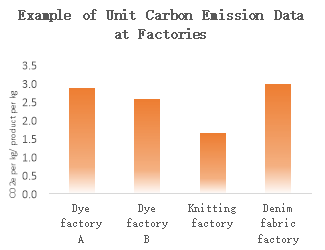

Texhong International Group has established carbon footprint management teams in the yarn segment and the garment fabrics and apparel segment respectively, with its main tasks of monitoring the energy usage and the environmental impact of the production process, setting energy conservation targets and implementing energy conservation and emission reduction projects.

For our yarn segment, cooperation with the Office for Social Responsibility of China National Textile and Apparel Council is in place to complete the carbon emission measurement for the production process of key products such as using TENCEL through the full life cycle assessment(LCA)model, and to provide corresponding carbon emission reports according to customers’requirements.In 2021, for the yarn segment, we shall further cooperate with upstream and downstream enterprises to complete the evaluation of carbon emission in the whole production process of our major products such as yarns made of TENCELand MODAL.

For our garment fabrics and apparel segment, impact of carbon emissions in the production process is also assessed through HIGG Index FEM 3.0, a third-party platform, so as to formulate corresponding solutions for reducing the social and environmental impact of the production process.

Texhong International Group actively responds to a series of medium to long-term goals and plans on climate change of China such as reaching carbon peak in 2030 and carbon neutrality in 2060, so as to continue its attention and reduction on the impact of carbon emissions at different stages such as raw material procurement, transportation and logistics and production operations. At present, having some of the raw materials approved with carbon neutrality certification, the Group is also optimizing its transportation and logistics, checking the carbon emissions of each factory and formulating specific plans for energy saving and carbon reduction to continuously lessen the carbon footprint and related environmental influence of its products.

The procurement department and the technical departments of Texhong International Group regularly obtain information on sustainable materials from the market, and give priority to low-carbon and eco-friendly materials in the selection of raw materials, including natural sustainable fibres, regenerated fibres and biodegradable fibres. Meanwhile, with advanced production technologies, we further reduce carbon emissions generated during the production process.

We give priority to suppliers and partners with outstanding sustainability performance, so we encourage suppliers to use clean energy, improve production efficiency, use sustainable raw materials and support certified global projects of carbon reduction in order to achieve reduction and elimination of carbon emissions.For example, our major supplier of regenerated cellulosic fibres has been approved with a Science-based targets(SBT)and have signed the“Fashion Industry Charter for Climate Action of the United Nations”, which has set a target to achieve net zero emission of carbon dioxide by 2050.Texhong International Group has purchased a variety of zero-carbon products such as Lyocell and MODAL fibres from this regenerated cellulosic fiber supplier, to reduce the carbon footprint of its products.

The Group has set up textile factories in the PRC, Vietnam, Mexico, Turkey, Nicaragua and other countries to directly reduce carbon emissions during transportation through global distribution of production capacity and in a manner of local procurement and local sales. For example, the plant of Texhong International Group in Nicaragua actively uses chemical products produced in its surrounding areas. This not only reduces carbon emissions from long-distance transportation from the PRC, but also sparks the growth of local economies and technical capabilities.

Concurrently, we continue to optimize our logistics approach and encourage centralized procurement to reduce the increase in transportation costs and carbon emissions in batches.

For our garment fabrics and apparel segment, flowmeters have been installed in all production machines to record the daily consumption of electricity, natural gas, petroleum gas, steam, diesel and other energies which will be utilized as the bases for energy conservation assessment.Based on the energy consumption in each process, we deeply explore energy-saving means at the technical and mechanical level so as to achieve energy-saving goals.

For our garment fabrics and apparel segment, three-year energy-saving target and plan have been set, thereby reducing a certain proportion of energy consumption per unit of production and related carbon emissions. Part of the energy-saving plan is as follows:

|

Item |

Commencement date |

Completion Date |

Energy saving |

|

Installation of MES energy monitoring system to automatically calculate the actual energy consumption per work order;

|

October 2021 |

June 2022 |

Steam of 3,000 tonnes/year

|

|

Replacement of open water boxes to reduce steam consumption;

|

October 2021 |

June 2022 |

Steam of 8,000 tonnes/year

|

|

Use of wet mercerisation to reduce steam consumption for drying;

|

October 2021 |

June 2022 |

Steam of 1,400 tonnes/year

|

|

Use of nitrogen for fire extinguishment instead of steam to reduce steam consumption; |

January 2021 |

July 2021 |

Standard coal of 1,300 tonnes/year and reduction of CO2 emission of 3,458 tonnes/year

|

|

Energy-saving upgrade project for continuous bleaching of knits |

January 2021 |

June 2021 |

Standard coal of 330 tonnes/year and reduction of CO2 emission of 878 tonnes/year |

For the yarn segment, two factories have been equipped with photovoltaic power system on their roof which could generate photovoltaic power of approximately 146 million KWh wholly deployed in the production process. In addition, part of our energy-saving plan for the yarn segment is demonstrated as follows:

|

Item |

Commencement date |

Completion Date |

Energy saving |

|

Reducing the power consumption per tonne of standard yarn by improving production efficiency, eliminating high-energy-consuming equipment, initiating power-saving upgrade and other means |

January 2021 |

December 2021 |

Power consumption in 2021 decreased from 2475 KWh/tonne in 2020 to 2450 KWh/tonne |

|

power-saving upgrade and other means |

|

|

|

|

Reducing the annual steam consumption per tonne of standard yarn by pipeline heating and other means |

January 2021 |

December 2021 |

Steam consumption in 2021 remained stable as compared to 2020 at 0.2 m3/tonne |

Since 2006, Texhong International Group jointly with its suppliers, have been integrating the concept of environment protection into products from the perspective of green and sustainability, to create green products with zero carbon or low carbon which are comfortable to use.

Texhong International Group is committed to the principle of sustainability as a standard for sustainable raw material procurement.Our“Sustainable Procurement Policy”describes our commitment to incorporating sustainability principle into our procurement decision-making.

We use eco-friendly raw materials for our products, including materials for recycling, reuse, green planting and Regarding all of the cotton that we source and FSC-certified viscose, 100%of their origins could be traced.

|

Type |

Percentage |

|

Cotton meeting sustainable plantation standards

|

In 2020, majority of the cotton purchased by the Group could meet the sustainable plantation standards, of which:

|

|

Viscose verified by Forest Stewardship Council(FSC)/Programme for the Endorsement of Forest Certification(PEFC) |

8.2%of our viscose procurement |

|

Recycled Polyester |

40%of our total polyester purchases |

(I)Natural sustainable fibres

Organic cotton certified by the Global Organic

Textile Standard;

Organic cotton certified by the Global Organic

Textile Standard;Hemp and organic cotton can reduce carbon emission of 45%as

compared to conventional cotton;

(II)Renewable raw material fibre

(III)Regenerated fibres

(IV)Biodegradable fibre

(V)Eco-friendly dyestuff

We have replaced traditional chemicals with eco-friendly one that have obtained

Cradle-to-Cradle certification so as to reduce chemical consumption, alleviate sewage treatment

pressure, and contribute to the improvement of water ecological environment:

We have replaced traditional chemicals with eco-friendly one that have obtained

Cradle-to-Cradle certification so as to reduce chemical consumption, alleviate sewage treatment

pressure, and contribute to the improvement of water ecological environment:

In addition to purchasing raw materials with organic certification, FSC certification or Cradle-to-Cradle certification at the procurement stage, the Group fully considers the environmental and health attributes of products during product design and production.

|

International certification for some of our yarn and fabrics apparel products |

|

|

Global Recycling Standards |

Statement Criteria for Recycling Content |

|

|

|

|

Global Organic Textile Standard(GOTS)Certification |

Organic Content Standard(OCS)Certification |

|

|

|

Texhong International Group continues to promote the use of sustainable cotton

such as organic cotton, CMIA African cotton and recycled cotton with suppliers and downstream

fabric and garment companies, and to obtain organic certification in the areas of factory

production, storage, environment and trading by third-party certification institutions.

Texhong International Group continues to promote the use of sustainable cotton

such as organic cotton, CMIA African cotton and recycled cotton with suppliers and downstream

fabric and garment companies, and to obtain organic certification in the areas of factory

production, storage, environment and trading by third-party certification institutions.

Meanwhile, Texhong International Group as one of the first team of members of the Cotton LEADS jointly established by the cotton industries in both Australia and the United States, has actively participated in the systems for sustainable certification of the two major source countries of quality cotton.

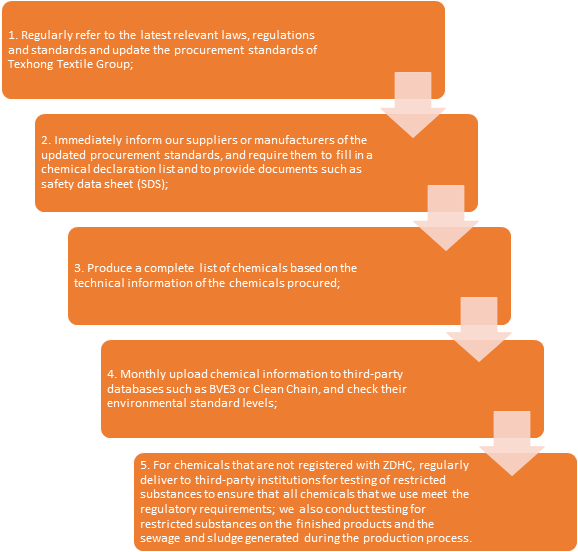

Texhong International Group strictly abides by the regulations or requirements of countries and brands on chemicals, and strictly manages chemicals used in areas such as production and water treatment, covering the storage and use of chemicals and the handling of hazardous wastes.

The Group has established a system that fully complies with the“Registration, Evaluation, Authorisation and Restriction of Chemicals(REACH)”of EU.We have also made reference to the Zero Discharge of Hazardous Chemicals(ZDHC)and other standards which are more stringent in terms of chemical management, and have set up self-contained standards in accordance with customers’requirements, so as to actively reduce or prohibit the use of substances that become the burden to the environment in our products.

|

Objective |

Status |

|

Chemicals that we used 100%meets the relevant requirements of REACH |

Satisfactory |

|

More than 65%of the chemicals that we used can reach ZDHC Gateway Level 1 or above |

Planned to be completed in 2022 |

|

Electronic database for storing all chemical information is updated to enhance document sharing and transparency on using chemicals |

Planned to be completed in 2022 |

Intrinsically or after normal processing, fabrics, of chemicals that we use must meet the following requirements:

|

Type |

Content |

Satisfaction of requirements |

|

Chemicals |

REACH SVHC |

Must |

|

Conflict Minerals |

Must |

|

|

Manufacturing Restricted Substances List(MRSL)of brands |

Must |

|

|

ZDHC MRSL Level 1 or above |

Priority |

|

|

EcoPassport of Oeko-Tex |

Priority |

|

|

GOTS |

Priority |

|

|

Fabrics |

Oeko-Tex Appendix 4 Class II |

Must |

|

Okeo-Tex Appendix 6 Class II |

Priority |

|

|

Restricted Substance List(RSL)of American Apparel&Footwear Association(AAFA) |

Priority |

|

|

CA Prop 65 |

Priority |

|

|

RSL of brands |

Priority |

![]()

We have established a list of

prohibited chemicals in accordance with the requirements of ZDHC MRSL, Oeko-Tex Appendix 6 and

brand. We require our suppliers to report the chemicals that they use based on the list.

We

shall follow the latest laws and regulations in a timely manner and update the list regularly in

accordance with customers’requirements.

Our list of prohibited chemicals

From the source, finished products to the full coverage of waste, the chemicals that we use will be ensured to be in compliance with the standards:

|

Item |

Commencement time |

Status |

|

Reducing the use of Perfluorochemicals(PFCs) |

January 2021 |

Completed |

|

Reducing quinoline in disperse dyes and vat dyes |

June 2021 |

Completed |

|

Replacing traditional wrinkle free formaldehyde resins with formaldehyde-free resins |

May 2021 |

In progress |

|

Replacing traditional reactive dyes containing p-chloroaniline with reactive dyes that do not contain p-chloroaniline |

May 2021 |

In progress |

? Reducing the use of PFCs:

We conduct very advanced management of Perfluorochemicals(PFCs).Traditional polyester and cotton fabrics need the use of PFCs to achieve the performance of soil release.However, PFCs are restricted chemicals, where the European Stockholm Convention have stopped using C-8 PFCs by 2020.

Early in 2013, Texhong International Group has 100%eliminated the use of C-8 PFCs and changed to use the C4 or C6 PFCs which are more eco-friendly.Concurrently, we actively invest resources in commencing research on substitutes for PFCs such as the C6 and C4 types.Since 2014, we have begun to use a significant amount of non-fluorinated chemicals to ensure that their waterproof effect can fully meet the requirements of customers with environmental protection and health guaranteed.

However, there are still technical difficulties in terms of oil repellent performance and soil release and finishing for technologies on non-fluorinated chemicals, making it difficult to achieve large-scale commercialization. Texhong International Group has continued to inject resources and, sparing no efforts, finally discovered a non-fluorinated finishing material for soil release, a hydrophile that can meet our customers’requirements, enabling further reduction on our consumption of PFCs. In June 2021, the percentage for our use of non-fluorinated(PFCs Free)hydrophile finishing material has mounted to 82.9%. The Group will continue to conduct research on and develop new technology for dyestuff and our production processes to further reduce the use of restricted chemicals.

|

Chemicals |

Percentage as at March 2021 |

Percentage as at June 2021 |

|

PFCs Free hydrophile finishing material |

77.4% |

82.9% |

|

PFCs |

22.6% |

17.1% |

? Reducing the formaldehyde content in chemicals:

Traditional wrinkle free finishing of cotton requires the use of chemicals containing formaldehyde, and it is required in the general market that the formaldehyde content of wrinkle free fabrics should be less than 60 ppm.In order to provide consumers with healthier products, Texhong International Group has developed a finishing material with wrinkle free formaldehyde-free resin.At present, about 17%of the wrinkle free finishing auxiliaries of our factory in Vietnam have been replaced with formaldehyde-free resin.Its effect is basically the same as that of the traditional wrinkle free resin and has been certified by the FITI Testing&Research Institute, a third-party testing institution, as the formaldehyde on the fabrics cannot be detected(less than 16 ppm).

For products with chemical risks, we shall provide our customers with a safety data sheet(SDS)or Fabric Data Sheet specifying related information such as the name and content of, the risk alert and first aid measures for the chemicals.

“Consistent product quality to meet customers’needs”is the quality objective of the Group.

The Group has developed a number of new technologies and products with a focus on pure cotton products, including elastic pure cotton core-spun yarn series, high-end yarns and garment fabrics for knitting, through independent R&D and cooperation with renowned domestic and international fabric developers and research institutions.Meanwhile, spares no effort to promote environmentally friendly raw materials and contribute to sustainable environmental development

As at the end of 2020, five subsidiaries established an ISO 9001 quality management system and obtained third-party certification.In order to ensure product quality, the Group has established a quality assurance inspection system and clearly defined the job responsibilities, inspection requirements, inspection frequency, etc.of each responsible person, and requires each inspector to conduct inspection for the purpose of solving problems and achieving effective control, and to supervise rectification and ensure quality.

Bills of Material for Products

The following are the bills of material for the Group's products, while the materials used and their proportions will be adjusted according to the specific conditions of the products.We promise that the materials used meet environmental and health standards.

Product | Formula |

Yarns

|

|

Grey fabrics

|

|

Colour good |

|

Denim fabrics

|

|

Apparel

|

|

The business philosophy of the Group is to expand market share with brand name and improve customer satisfaction.Consumers’opinions and suggestions would be analyzed comprehensively in order to improve the quality of products and services constantly and boost customer satisfaction in every possible way.

Market intelligence department of the Group conducts biannual satisfaction surveys on major customers who have purchased the Group’s products and invites them to complete“Customer Satisfaction Questionnaire”.In accordance with aftersales quality management requirements, professionals of the Group offer all rounded services for products sold and have been widely recognized by customers

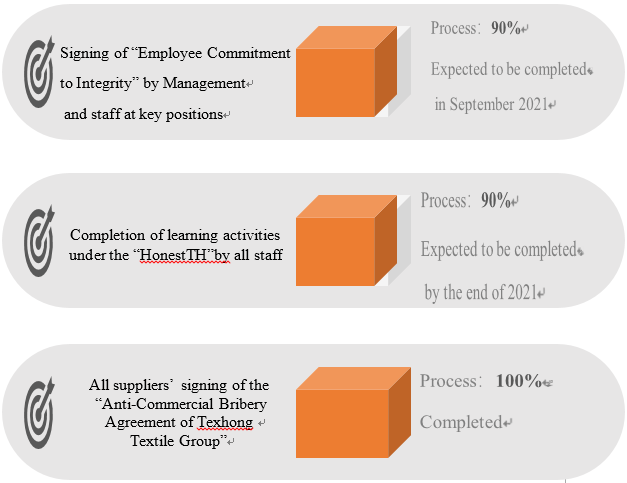

“Business Integrity”is the most important core value of Texhong International Group, and it is our commitment to manage the Company with the highest standards.

In our daily operations, we have detailedly implemented the concepts of integrity, fairness and transparency, and have zero tolerance on corruption, and do not allow any acts of bribery, fraud, extortion, abuse, misappropriation of the Company’s assets or sacrificing the Company’s interests in exchange for personal interests.Therefore, we have formulated a set of ethical guidelines, including the“Code of Conduct for Employees”and the“Code of Conduct for Suppliers”, which set out the principles applicable to all employees, contractors and suppliers of Texhong International Group and regulate our daily operation.

The board of directors is the highest governing body for the Group's business ethic management:

Audit Committee

It is responsible for supervising the compliance of the code of

conduct, standards and policies guiding the Company.

Office of the Director-General of the

Group

Being the central management body for anti-corruption of the

Group, it is responsible for:

Subsidiaries

They are responsible for preparing specific measures to prevent all kinds of

corruption according to the actual situation;they are also responsible for investigating or cooperating

unconditionally with the Office of the Director-General of the Group to investigate the Company’s

internal corruption, and to deal with it in a timely manner according to the Company’s

system.

The Group conducts audits for all its companies once every three years through the Internal Audit Department of the Group led by the Office of the Director-General.

Form of audit:Special audit for mainly the operational departments at the group level as well as all relevant departments or independent audit of subsidiaries.

Audit plan:Developed by the Internal Audit Department.

Between June 2017 and October 2020, we have completed the audit work for all our companies in the aspects of sales process, logistics and transportation process, fixed asset handling process, non-performing assets, etc., and no corruption or bribery was found.

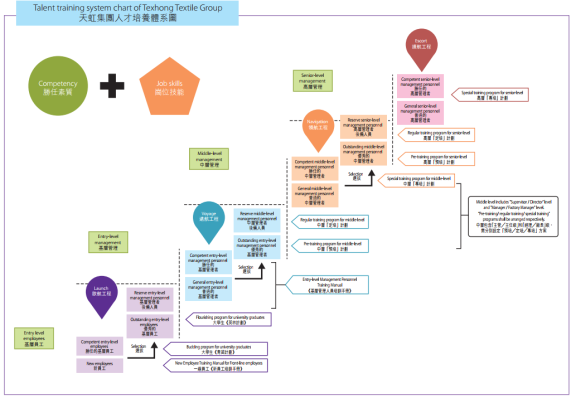

The Group formulates a training plan every year, covering all types of employees including the full-time and the part-time.

We provide employees with training on ethical standards through email advice, signing relevant agreements on professional integrity and training on rules and regulations.According to the training programme, we have invited the Independent Commission Against Corruption of Hong Kong to conduct anti-corruption related training for all directors of the Group on 23 August 2021.The training lasted for 1 hour.Training on ethical standards for all types of employees would be completed by the end of 2021.

Staff training is one of the important human resource investment of the Group and also an effective incentive. The Group has established a comprehensive talent training system, including professional leadership training covering all management and skill training covering all types of employees.We continue to improve Texhong Education College structure for training, learning course, technician, mechanist/engineer skill assessment, mid-toentry level training and senior leadership. Meanwhile, we formulate training plans for each subsidiary every year, arrange staff training according to the training plans every month, and make record for the number of training courses, training time, number of staff who have completed training and other information.

The Group has also formulated incentive policies to encourage employees to obtain professional certificates or to complete corresponding professional courses:

1) According to the academic background such as master's degree, undergraduate, tertiary place or 211 or 985 colleges of the staff, salary will be provided in line with the market level.

2) Employees who have obtained the certificate of electrician will be rewarded with certain allowances.

3) A technician appraisal is developed for equipment operators.Besides, assessment on relevant personnel is conducted annually to determine the corresponding levels of allowances that our qualified technicians will receive.

The Group has set up a comprehensive performance incentive policy, covering all types of employees:

? For all management personnel, monthly and year-end comprehensive performance appraisals

are mainly adopted.

? For salesmen, monthly commission performance appraisal is mainly adopted.

? For factory workers, wages based on output and year-end pay for performance are mainly adopted.

We conduct employees’satisfaction surveys every year by offline or online questionnaires, covering working environment, salary package, dormitory environment and meals at canteen, so as to make timely improvement according to the satisfaction survey results.

The Group has been committed to giving back to society over the years.For instance, we acquired bankrupt cotton textile enterprises in the People’s Republic of China and offered better remuneration package and living security for retained staff. We proactively recruited ethnic minority employees in order to improve their living quality with job and education opportunities.Being enthusiastic in social welfare, we made donations every year and hired disabled employees so that they can support themselves financially. The Group established the“Charity and Social Welfare Management Policy of Texhong International Group”for organizing charity and welfare activities.

Since the outbreak of COVID-19, the Group has actively assisted in the fight against the epidemic and fulfilled its corporate social responsibility.

In February 2020, the Group donated RMB5 million through the charity federation of Jiangsu, Shandong and Xinjiang for the purchase of supplies for epidemic prevention and control. Shandong Lanyan sped up its production of more than 20,000 protective isolation suits and more than 30,000 protective isolation caps to support epidemic prevention and control work of local governments so as to provide protection for the safety of epidemic prevention personnel;

In March 2020, all Party members of Shandong Lanyan donated a total of RMB10,000 to various branches to fight against the epidemic, contributing to the prevention and control of the epidemic;

In June 2020, Taltex(Zhuhai)donated RMB100,000 to Zhuhai Red Cross to support the Red Cross.

In 2020, Texhong Yinlong and Texhong Galaxy donated VND200,000,000 to the victims who suffered from flooding in central Vietnam to help them to rebuild their homes with the help of enterprises.

In 2020, Texhong Renze provided bases for visiting and exchanging and internship from the Department of Chinese Language of Ho Chi Minh City Normal University, the Department of Chinese Language of Hue University College of Foreign Language, the textile profession of the Second Industrial University College of Ho Chi Minh City, Ho Chi Minh City University of Technical Education and the University of Technology.

In 2020, all employees from Texhong Winnitex and Texhong Yinlong donated nearly VND14,000,000 and VND160,000,000 to the people in central Vietnam who suffered from flooding respectively, helping them overcome difficulties

In May 2020 and July 2021, the Group donated RMB86,000 and RMB860,000 to the government of Quang Ninh Province, Vietnam, respectively, and donated in February 2021 the nucleic acid testing reagents for the COVID-19 worth RMB300,000 to assist the Vietnamese in winning the battle against the COVID-19 as soon as possible.

|

|

Texhong Yinlong:Donations to Flood Victims in Central Vietnam | Texhong Galaxy:Donations to Flood Victims in Central Vietnam |

|

|

Texhong Renze:Providing Internship Bases for Visits and Exchange | Texhong Winnitex:Disaster Relief Donations |

“Sustainable Procurement Policy”

“Code of Conduct for Employees”

“Code of Conduct for Suppliers”

“Principle of Prohibition of forced labour”

“Incentive Scheme for Integrity and Self-discipline of Texhong International Group”

“Whistleblower Protection and Reward System of Texhong International Group”

“Contributions&Other Spending”

“Tax Strategy and Governance Policy”

“Environmental Policy&Commitments”

In 2020, the Group was awarded TOP 100 in the China’s Best Employers during Covid-19 jointly issued by 51 job.com and Hurun Report, in recognition of our rapid response to the outbreak of COVID-19 by actively utilizing human resources to maintain the normal operation of the Group while safeguarding the interests, safety and satisfaction of employees to the greatest extent, and our full assumption of social responsibilities.

In 2020, the Group was awarded TOP 100 in the China’s Best Employers during Covid-19 jointly issued by 51 job.com and Hurun Report, in recognition of our rapid response to the outbreak of COVID-19 by actively utilizing human resources to maintain the normal operation of the Group while safeguarding the interests, safety and satisfaction of employees to the greatest extent, and our full assumption of social responsibilities.

Related Links:

|

|

|

|